Relocation of a shut-down particleboard production line from Spain to Portugal

As part of the retrofitting project for the Luso-Finsa site in Nelas, Portugal, we were commissioned with the relocation of a particleboard production plant from Spain to Portugal. In the future, the client intends to produce combi-boards made of particles and fibres.

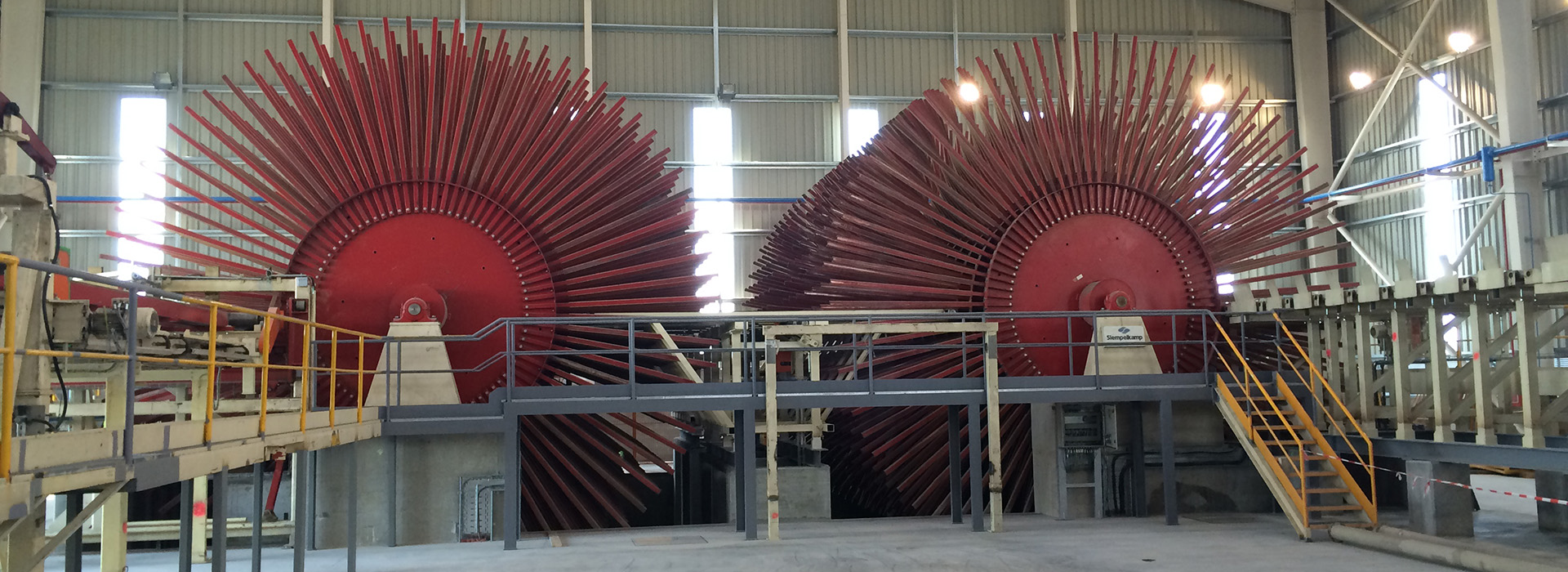

Our order volume comprised all the machinery and equipment, from the particle preparation system including sifter, dry particle bin, resination system and forming line up to the ContiRoll® press including cooling and stacking line. Also, we dismantled the entire supporting structure, the extraction systems, the pneumatic conveyors and filter plants and were responsible for their transport to Portugal. The whole transport order comprised several special and heavy-duty transport units resulting in more than 100 full truck loads.

With the dismantling in Spain coming to an end, we deployed another crew at the Portuguese site, who started to reassemble the first incoming deliveries. Parts of the press had to be reworked by the manufacturer in Germany before we were able to reassemble them. As there was only a precisely defined time window available, we had to dismantle the equipment in shift work to meet the schedule.

In the course of reassembly in Spain we modified the particleboard production plant retrofitting the forming line with another two fibre mat formers. Besides, we furnished the ContiRoll® with some new elements by Siempelkamp and extended the press by about 6.5 m.

- Client: Finsa

- Customer: Luso-Finsa

- Place of installation / country: Teruel, Spain / Nelas, Portugal

- Duration: June 2014 – April 2015